Having added battery storage to my home energy system, a dilemma has been created; and that dilemma is how to prioritise the different uses for where home generated electricity can go.

To be clear what these uses are, and to place them in a descending order of rank, they are:

- the moment by moment electricity needs of our house

- domestic hot water heating (DHW), - or more precisely, topping up the temperature thereof from the temperature reached by a log burning stove whose back-boiler also supplies central heating warmth to radiators, and never gets to be > 40° C

- charging the battery of our BYD home energy storage system (10.2 kWh of storage, max. input / output capacity of battery inverter is 3.7 kW)

- charging the battery of our old model, Nissan Leaf EV (which has the smaller 3.3 kW on-board charger)

Apart from the dilemma of ordering the prioritisation of these loads, there is the matter of devising a way of ensuring that home generated electricity goes where I want it to; and in order for it to be possible to make it go where I want it to, for that I have to have some means of 'seeing' where power is going at any given moment.

Another fundamental matter to be clear about is the philosophy I follow for how I want my home micro-grid to operate; although I am grateful for any savings I make on needing to buy-in grid energy, I am not in the business of 'doing home generation' for the sake of making money; my hydro and solar installations are both accredited for Feed in Tariff payments, and there is thus a nice revenue stream coming from those; beyond that source of income, fancy schemes such as are offered by Octopus Energy, - a company offering attractive reduced tariffs for bought-in energy at certain times of the day, and generous Smart Export Guarantee (SEG) tariffs for exported energy, - these I view as 'baits' simply to get me to sign up, and for me they hold no appeal whatsoever.

Rather, the philosophy that guides me is one of simple self-sufficiency, - the contented feeling of being able to cook, light the house, bath in hot water, and travel the limited distances we need for shopping, - and know that all the energy for these things has come from one's own 'power station', using 100% renewable energy.

At the time of writing, in January 2024, my home battery storage has been up and running for just 3 months, and those three months have been exceptionally wet; as a result the Powerspout has been producing at maximum output (900W) almost continuously and its 24 hour total output of 21.6 kWh has been more than enough energy to supply all our needs; in fact much of the time there has been so much energy that there has been some to spare which, rather than let it go out to the grid, I divert to one or both of two subsidiary loads; one of these is a DHW load and the other a space heater load, and both are in a part of the house which is presently not occupied; though unoccupied, sending power there helps to keep away the winter chill in that part of the house.

Visualising and controlling how electricity is being used around my home is crucial.

The 'visualising' is made easy with an iPad because each bit of kit in the system can be called up in the local area network (LAN) or via SMA's Sunny Portal interface; thus the battery state of charge (SOC), the power flow at the grid connection point, the total of home generation from combined hydro and solar, whether the inverter is charging or discharging the battery, and which load the DHW diverter is feeding to, - all these are accessible from the comfort of an armchair.

Controlling is achieved with no less a degree of ease; it involves a certain amount of 'automaticity' and a certain amount of 'manual tinkering'.

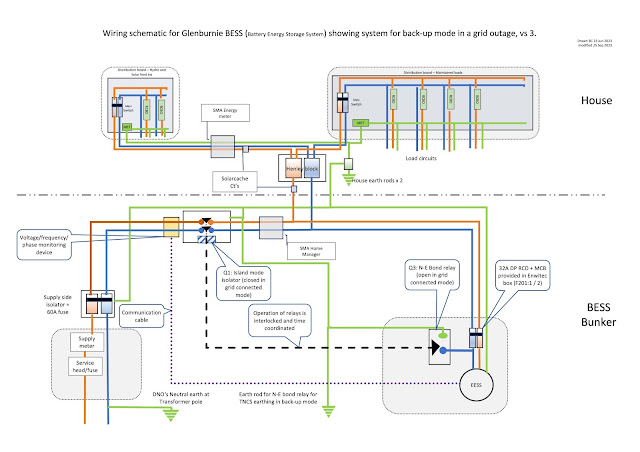

Careful scrutiny of the single line diagram below indicates that the design of my system ensures that diversion to heating DHW is the first priority for where surplus home generation goes; the diversion device controlling this is a Solarcache, and by way of it, two priorities of load are controlled; when the first priority load, which is the main house DHW supply, is up to temperature and its thermostat is OFF, the second priority load is switched ON; as a result of the way I have set it up, the second priority load is comprised of the two loads previously mentioned, one being the subsidiary DHW load and the other the space heater load, both located in the chilly part of the house.

.jpg)

Each of these 3 Solarcache loads (one on first priority and two on second priority) is wired from the main consumer unit via its own dedicated RCBO (residual current breaker with overload), and whether a load is capable of receiving power is easily controlled by manual operation of the RCBO switch; thus 'automaticity' is achieved by the way Solarcache switches between its two priority options, and 'manual tinkering' by the RCBO switches, which determine which, if any, of Solarcache's connected loads is actually available to receive power.

Happily the RCBO switches are very close to the armchair previously mentioned, and that makes 'visualising' and 'control' not only a convenient task, but a fun one too.

So much for the basic layout of how electricity is used around my home for meeting the first two priorities on my list, - the moment by moment power needs of the house and using any surplus primarily to heat DHW.

In Part 2, I'll explain how the BYD storage battery is kept charged, how the Nissan Leaf is charged from stored energy in the BYD battery, and why the technology of a MyEnergi Zappi doesn't seem to have a place in my set up.

.jpg)